I-Automatic Pizza Production Line

Izici zomkhiqizo

•Isisetshenziswa sokunamathisela esizenzakalelayo esizenzakalelayo, idivayisi yokusabalalisa yokugcwalisa ngokuzenzakalelayo kanye nedivayisi yokuphinda uthole izinto ezibonakalayo

• Idizayini ye-Modular, inhlanganisela eguquguqukayo, izinga eliphezulu lokuzenzekelayo, inqubo enokwethenjelwa

• Ukujiya kwebhande lenhlama nesivinini sokugijima kungalungiswa ngesistimu yokulawula ehlakaniphile

•Ububanzi bokusebenza bebhande bungu-600mm kuya ku-1600mm

•Umthamo wezisetshenziswa: 1.5t-2.0t/h

• Usayizi womkhiqizo: ububanzi ngokuya ngezidingo zomkhiqizo

• Isisindo somkhiqizo: 30-350g ngokuvumelana nezidingo zomkhiqizo

Ukucaciswa Komkhiqizo

| Usayizi Wezisetshenziswa | 30000*5300*2500MM |

| Amandla Wezisetshenziswa | 35KW |

| Isisindo Sezisetshenziswa | 5560kg |

| Impahla Yezisetshenziswa | 304 Insimbi Engagqwali |

| Izisetshenziswa Voltage | 380V/220V |

- I-Dough Hopper

Inhlama exubile ithululelwa ku-hopper yokudla yomshini we-bakery waseDanish ngokusebenzisa ikheshi, futhi isisindo esisodwa sokudla siklanyelwe ngokwamandla okukhiqiza umugqa wokukhiqiza, ukuze kuqinisekiswe ukuthi ozakwabo ngokucutshungulwa njalo kwenhlama abakwenzi. linda isikhathi eside inhlama.

-Ukwakhiwa Kwenhlama

Uhlelo lokwakha ibhande lenhlama luthatha indlela ephansi yokucubungula ukucindezeleka ukuze kucutshungulwe ngobumnene ibhande lenhlama libe ububanzi obudingekayo nobukhulu, ukuze lingalimazi ukwakheka kwenhlangano yebhande lenhlama futhi kuqinisekiswe ukuthi inhlama ithambile.

-Isistimu yokuphumula yenhlama neyokupholisa

Ibhande lenhlama lithuthelwa emhubheni wokuphumuza izinga lokushisa eliphansi, elixegisiwe njengoba kudingeka ngokwezidingo zenqubo yekhasimende ngalinye.Umhubhe wezinga lokushisa eliphansi ufakwe idivayisi ye-anti condensation, ukuze inhlama ingeke yomiswe futhi iqhekeke ngaphandle kokushaywa ngokuqondile.

- Ukugingqika kwesathelayithi

Umbhoshongo wesathelayithi wohlobo lwenhlama egoqayo uphatha ngobumnene ibhande lenhlama, usakaza igrisi nebhande lenhlama ngokulinganayo, futhi ibhande lenhlama ligoqwa ngokuphindaphindiwe ukuze lenze ibhande lenhlama elinobubanzi nokuqina elibekwe enanini elisethiwe, elithunyelwa enhlama. uhlelo lokwakha ibhande, olwaziwa nangokuthi uhlelo lokubumba isinkwa embonini

-I-roller yokulinganisa

Ububanzi nobukhulu bebhande lenhlama elinwetshiwe ngokusebenzisa amaphasi amaningi okugoqa kunqunywa ngokuvumelana nezidingo zenhlama egoqayo.Ugqinsi lomkhiqizo wokugcina oludingwa uhambo lunqunywa ngokwezidingo zamandla okukhiqiza.

-I-roller yokulinganisa

Ububanzi benhlama egoqayo bunqunywa ngokuvumelana nezidingo zamandla okukhiqiza.Singahlinzeka ngobubanzi bemishini engu-680-1280mm ukuze sihlangabezane nezidingo zamandla okukhiqiza amakhasimende ahlukene.

-Ukushanela ufulawa

- Ukushanela okubili phansi

- Ukushanela okuphezulu

- Ukulungiswa ngesandla kobude bokusebenza.

- Ukulungiswa ngesandla kwe-angle yokusebenza

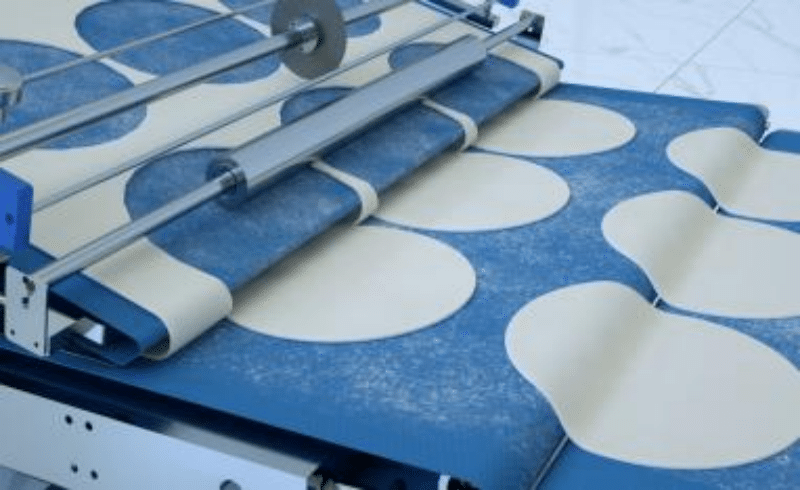

-Ukusika isithende

Ngemuva kokugqoka, lapho ibhande lenhlama ligijimela esigabeni sokwenza inhlama ngokusho kobukhulu obudingekayo nobubanzi, lisikwa ngokusika isithende ukuze kuqinisekiswe ukuthi i-pizza iyindilinga ncamashi.

-Residual Recovery

I-pizza esikiwe futhi enomumo ithuthelwa ebhandeni elilandelayo, bese inhlama esele igaywe kabusha futhi iphinde isetshenziswe ngebhande lokugaywa kabusha.

-Ukugcwalisa idiphozi

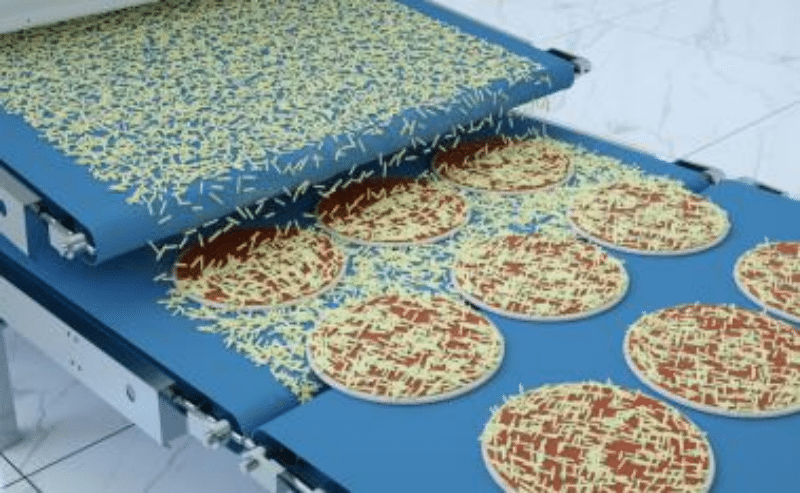

I-pizza esikiwe futhi enomumo ithuthwe igcwalisa idiphozithi, Lo mshini uzothela isoso katamatisi ebusweni be-pizza.

-Ukugcwalisa ushizi kanye nemifino

Ngokuthelwa koshizi nemifino okuxubene nebhande. futhi ukugcwaliswa okuyinsalela kuye kwadluliselwa esinyathelweni esilandelayo.

Umbukiso Womkhiqizo

Imininingwane yokusebenza