Umshini Wokubhaka I-Baguette Production Line

Izinzuzo zemishini

Isingeniso Sezisetshenziswa-Umshini Wokubhaka Okuzenzakalelayo Umshini Wokubhaka I-Baguette Umugqa Wokukhiqiza

Idizayini eyinhlanganisela ye-modular iyamukelwa ukuze kutholakale ukukhiqizwa okuhlukahlukene ngokuhlanganiswa okuguquguqukayo nokulula.Izinga eliphezulu elizenzakalelayo nendawo yokusebenzela ehambisanayo.

Izinto ze-SUS304 zomzimba wonke, ziqinile futhi zihlala isikhathi eside.

Idizayini yethu ikwenza kube lula ukuhlanzwa nokugcinwa kahle

Amabhande enhlama ububanzi ububanzi 600-1600mm

Xhumana nathi ngebhizinisi lakho lokwenza isinkwa esithengiswayo!

Ulayini wokukhiqiza isinkwa ngomshini nawo usiza ekumisweni komkhiqizo kanye nokwenza ngcono ukuphepha kokudla

Ububanzi Bokusebenza Ibhande Lokuthutha

| 600mm | 1600 mm |

I-Dough Hopper

Inhlama exubile ithululelwa ku-hopper yokudla yomshini we-bakery waseDanish ngokusebenzisa ikheshi, futhi isisindo esisodwa sokudla siklanyelwe ngokwamandla okukhiqiza umugqa wokukhiqiza, ukuze kuqinisekiswe ukuthi ozakwabo ngokucutshungulwa njalo kwenhlama abakwenzi. linda isikhathi eside inhlama.

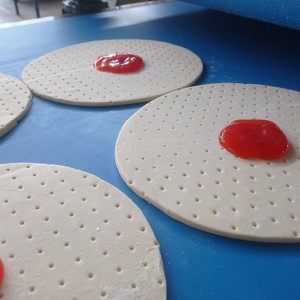

I-Dough Band Calender

Uhlelo lokwakha ibhande lenhlama lusebenzisa indlela yokucubungula ukucindezeleka okuphansi ukuze kucutshungulwe ngobumnene ibhande lenhlama libe ububanzi nobukhulu obudingekayo, ukuze lingalimazi ukwakheka kwenhlangano yebhande lenhlama nokuqinisekisa ukuthi inhlama ithambile.

Uhlelo Lokuphumula Inhlama kanye Nokupholisa

Ibhendi yenhlama ithuthelwa emhubheni wokuphumuza izinga lokushisa eliphansi, oxegisiwe njengoba kudingeka ngokwezidingo zenqubo yekhasimende ngalinye.Umhubhe wezinga lokushisa eliphansi ufakwe idivayisi ye-anti condensation, ukuze inhlama ingeke yomiswe futhi iqhekeke ngaphandle kokushaywa ngokuqondile.

I-Satellite Rolling

Umbhoshongo wesathelayithi wohlobo lwenhlama egoqayo uphatha ngobumnene ibhande lenhlama, usakaza igrisi nebhande lenhlama ngokulinganayo, futhi ibhande lenhlama ligoqwa ngokuphindaphindiwe ukuze lenze ibhande lenhlama elinobubanzi nokuqina elibekwe enanini elisethiwe, elithunyelwa enhlama. uhlelo lokugoqa ibhande, olwaziwa nangokuthi uhlelo lokuvula amakhekhe embonini

I-Gauging Roller

Ububanzi nobukhulu bebhande lenhlama elinwetshiwe ngokusebenzisa amaphasi amaningi okugoqa kunqunywa ngokuvumelana nezidingo zenhlama egoqayo.Ugqinsi lomkhiqizo wokugcina oludingwa uhambo lunqunywa ngokwezidingo zamandla okukhiqiza.

I-Calender

Ububanzi benhlama egoqayo bunqunywa ngokuvumelana nezidingo zamandla okukhiqiza.Singahlinzeka ngobubanzi bemishini engu-680-1280mm ukuze sihlangabezane nezidingo zamandla okukhiqiza amakhasimende ahlukene.

Ukushanela Ufulawa

- Ukushanela okubili phansi

- Ukushanela okuphezulu

- Ukulungiswa ngesandla kobude bokusebenza.

- Ukulungiswa ngesandla kwe-angle yokusebenza

Ibhande lokuhlukanisa

Ngemva kokugoqa nokugoqa izikhathi eziningi, lapho ibhande lenhlama ye-pastry elixegisiwe ligijimela esigabeni sokwenza inhlama ngokuvumelana nobukhulu nobubanzi obudingekayo, lihlukaniswa ngamabhande amaningana amancane ngomshini wokusika we-longitudinal wokugcwalisa noma ukugoqa.

Umshini Wokuhlela Nokuqondisa Ithreyi

Ithreyi ezenzakalelayo ngokugcwele yokuhlela nokuqondanisa idivayisi ingenziwa ngokuhambisana nobukhulu bethreyi yekhasimende, futhi inani lemikhiqizo lingabekwa ngokuya ngesidingo somthamo wokukhiqiza kanye nesidingo esikhulayo.Ngemva kweminyaka yokuthuthukiswa kobuchwepheshe, singabeka imikhiqizo kuwo wonke amathreyi.

-Ithreyi yokuthutha uhlelo

I-tray conveyor isetshenziselwa ukuthutha ithreyi elilayishwe i-embryo yenhlama liyise emshinini wokukhiqiza olandelayo ngeketango lokuthutha, bese liyithumela endaweni yokuhlola okuzenzakalelayo noma kumashalofu azenzakalelayo phezulu naphansi ngaphansi kwenqubo yomkhiqizo wokubhaka ogcwele, bese uyithumela. uyiyise embhoshongweni oqandayo ngokushesha ngaphansi kwenqubo yenhlama efriziwe ukuze iphole ngokushesha.